Concrete Pan Mixer Tilting pan / Bottom Discharge

Electrically operated - 3 phase supply. Suitable for efficient mixing of concrete prior to molding specimens in the laboratory for subsequent testing is essential if quality specimens are to be manufactured. The object of mixing is to coat the surface of all aggregate particles with cement paste, and bring the mix to a uniform condition. Pan or rotating drum mixer is suitable for the mixing of small quantities of concrete which are generally used in a Testing laboratory.

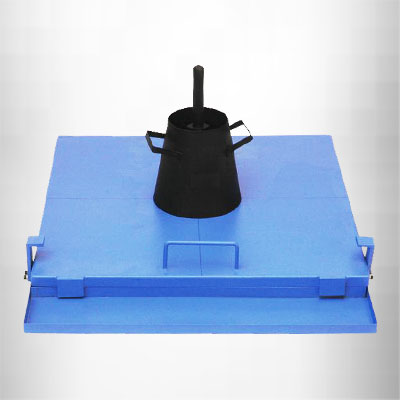

Flow Table, for flow of cement concrete

As per IS : 1199-1959, ASTM C-124, AASHO T-120, for determining flow of cement concrete. It consists of one Steel Table Top of 76.2 cm dia. Finely machined. One Conical Mould with handle 12 cm height having 17 cm. Top I.D. and 25cm base I.D. Supplied with a Tamping Rod 16mm dia. x 600 mm long., Suitable for operation on 230 v, 50 Cycles, Single Phase Mains, with Steel Top.

Slump Cone Test Apparatus

As per IS : 7320-1974. Consisting of Base Plate, One Cone & One Graduated Tamping Rod

Vee-Bee Consistometer

As per IS : 1199-1959. Consisting of a vibrating table size 380mm x 260mm mounted on a base with a motor. Working on 230 V, 50 Cycles, Mains, One Slump Cone, One Graduated rod fixed on a swivel arm with a plastic disc screwed in and One Tamping Rod 16mm dia. x 600 mm long.

Le-Chatelier Flask

As per IS : 4031-1988. Used for finding specific gravity of hydraulic Cement. Made from Borosil glass.

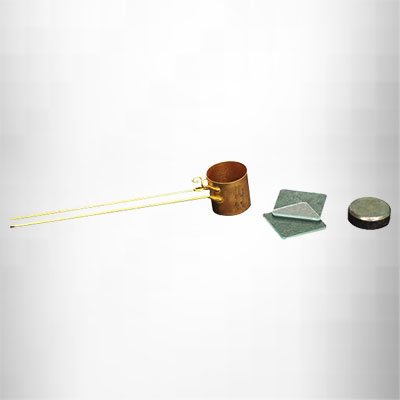

Le-Chatelier Mould

As per IS : 4031 (P-III), 269, 712, 5514, 1727, 2645 and 6932 (P-IX) it consists of a small Split Cylinder forming a mould with two parallel indicating arms. Supplied with two Glass Plates and one Lead Weight.

Vicat Needle Apparatus, with dashpot

As per IS : 4031, 2645, 2542(P-I), 1727, 5513 & 712, BS: 12 etc. It is used for determining normal consistency and setting time of cement and A Class limes. It consists of a Metallic frame with freely movable rod, One Vicat Mould Split type or Fulcrum Cone type, one Glass Base Plate and One Set of Needles, one each of initial and final needle and consistency plunger.

Cone Penetrometer for Mortar

As per IS : 2250 - 1981 (RA1995) with cone of 75mm dia. & 145mm long and conical container 150mm I.D. & 180mm deep with platform.

Tile Abrasion Testing Machine

As per IS : 1237-1980 RA 1996 with Digital Counter, Load applied is 30 kgf. A funnel is fitted to evenly spread abrasive powder on the grinding path. A pre set counter automatically stops the machine after 22 revolutions. This counter is re-adjustable. The machine works on 440 volts AC, three phase electrical supply. On request machine to operate on 230V AC. Supply can also be supplied.